真對不起,今天讓你們送了三次貨,下次會和倉庫那邊說清楚的。

貝格斯 Gap Filler 1100SF,Gap Filler 1100SF

或加微信公眾號“模切網”詢價

貝格斯 Gap Filler 1100SF

兩部件彩色協助為混合指示劑(體積比1:1)。混合系統將在室溫下固化。與固化的熱墊材料,液體的方法提供了無限的厚度變化不大或無應力在裝配位移。間隙填充1100sf,雖然表現出一定的天然粘性特征,不用于熱界面的應用需要一個機械結構鍵。

性能:

特點和好處

導熱系數:1.1 W/m無硅放氣或提取

超協調,專為脆性和低應力的應用環境和加速治療時間表

100%固體物,無固化副產物

間隙填充1100sf是硅敏感應用的熱溶液。材料為兩部分組成在室溫或高溫下固化。該材料具有低模量的性能,然后固化軟,彈性彈性體,有助于減少熱循環應力在操作過程中,幾乎消除應力在低應力應用程序。兩部件彩色協助為混合指示劑(體積比1:1)。混合系統將在室溫下固化。與固化的熱墊材料,液體的方法提供了無限的厚度變化不大或無應力在裝配位移。間隙填充1100sf,雖然表現出一定的天然粘性特征,不用于熱界面的應用需要一個機械結構鍵。

應用:

間隙填充1100sf可以混合和分配使用雙筒筒包與靜態混合器和手動或氣動槍或高容量的混合和分配設備(加熱可以降低粘度)

|

Temperature Dependence of Viscosity

|

|

The viscosity of the Gap Filler 1100SF material is temperature dependent. The table below provides the multiplication factor to obtain viscosity at various temperatures. To obtain the viscosity at a given temperature, look up the multiplication factor at that temperature and multiply the corresponding viscosity at 25°C.

|

|

Temperature

|

Multiplication Factor

|

|

|

°C

|

Part A

|

Part B

|

|

20

|

1.43

|

1.57

|

|

25

|

1.00

|

1.00

|

|

35

|

0.58

|

0.50

|

|

45

|

0.39

|

0.30

|

|

50

|

0.32

|

0.24 |

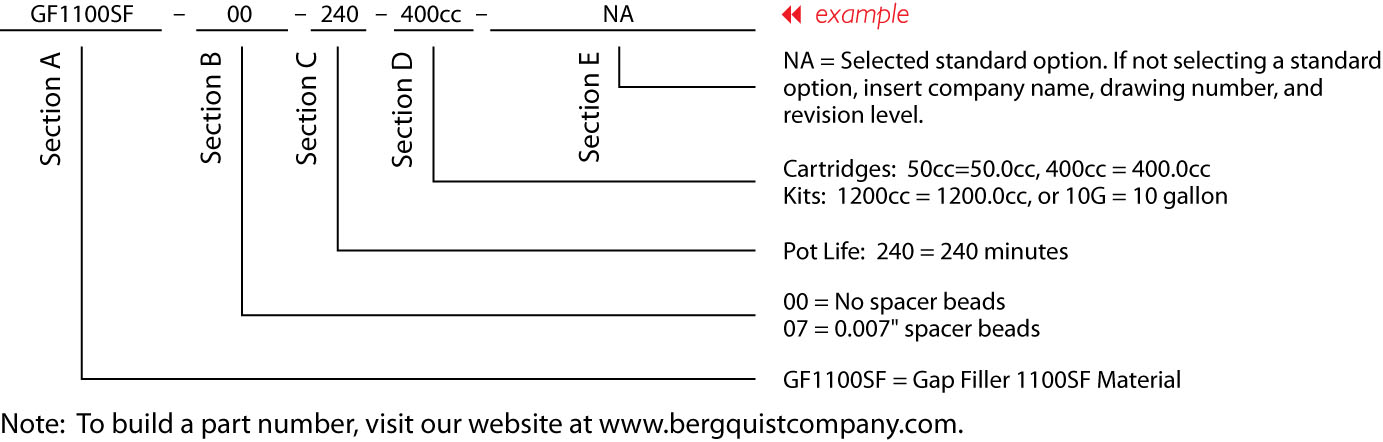

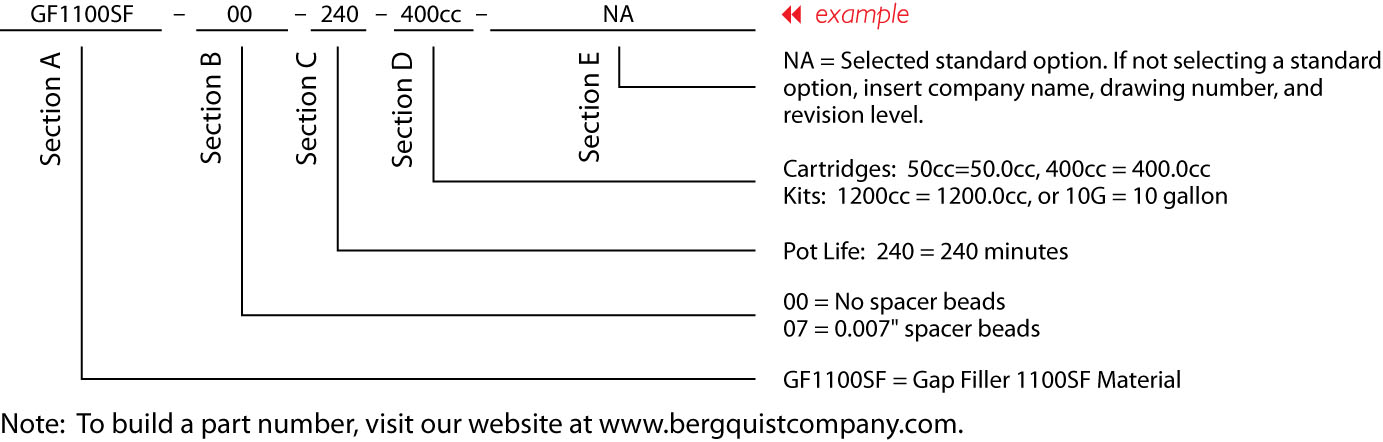

配置可用

- 提供產品或套件的形式

|

Typical Properties of Gap Filler 1100 SF

|

|||||

| Property |

Imperial Value

|

Metric Value

|

Test Method

|

||

| Color / Part A |

Yellow

|

Yellow

|

Visual

|

||

| Color / Part B |

Red

|

Red

|

Visual

|

||

| Viscosity as Mixed (cps) (1) |

450,000

|

450,000

|

ASTM D2196

|

||

| Density (g/cc) |

2.0

|

2.0

|

ASTM D792

|

||

| Mix Ratio |

1:1

|

1:1

|

***

|

||

| Shelf Life @ 25oC (months) |

6

|

6

|

***

|

||

|

Property As Cured

|

|||||

| Color |

Orange

|

Orange

|

Visual

|

||

| Hardness (Shore 00) (2) |

60

|

60

|

ASTM D2240

|

||

| Heat Capacity (J/g-K) |

0.9

|

0.9

|

ASTM E1269

|

||

| Continuous Use Temp (°F) / (°C) |

-76 to 257

|

-60 to 125

|

***

|

||

|

Electrical

|

|||||

| Dielectric Strength (V/mil) |

400

|

400

|

ASTM D149

|

||

| Dielectric Constant (1000 Hz) |

5.0

|

5.0

|

ASTM D150

|

||

| Volume Resistivity (Ohm-meter) |

1010

|

1010

|

ASTM D257

|

||

| Flame Rating |

V-O

|

V-O

|

U.L. 94

|

||

|

Thermal As Cured

|

|||||

| Thermal Conductivity (W/m-K) |

1.1

|

1.1

|

ASTM D5470

|

||

|

CURE SCHEDULE

|

|||||

| Pot Life @ 25oC (min) (3) |

240 min (4 hr)

|

240 min (4 hr)

|

***

|

||

| Cure @ 25oC (hours) (4) |

24

|

24

|

***

|

||

| Cure @ 100oC (min) (4) |

10

|

10

|

***

|

||

|

1) Brookfield RV, Heli-Path, Spindle TF @ 2 rpm, 25°C 2) Thirty second delay value Shore 00 hardness scale 3) Time for viscosity to double 4) Cure schedule (rheometer - time to read 90% cure) |

|||||

以下證明報告僅用于學習參考,請勿用于任何商業用途,模切網不承擔由此產生的任何法律責任。

SGS報告:

MSDS報告:

材質證明:

拿到,打開一看,很細心包裝都很好。

質量跟價格等同!很不錯后期繼續采購...

是正品材料價格還不錯,發貨也挺快。

品質檢測了,這次的貨都能達到我們的要求,馬上就會上機跑了.

這么大量的貨也能這么快送過來,你們備貨很多啊。

有新貨了,記得通知我

價格上有優勢,適合我們廠。