貝格斯 Bond-Ply LMS-HD

點和優點

導熱系數:1.4W

墊片材料厚度:0.254mm/0.305mm

阻燃等級:V-O

連續使用溫度:-60℃+180℃

特殊的介電強度

非常低的界面電阻

消除機械緊固件

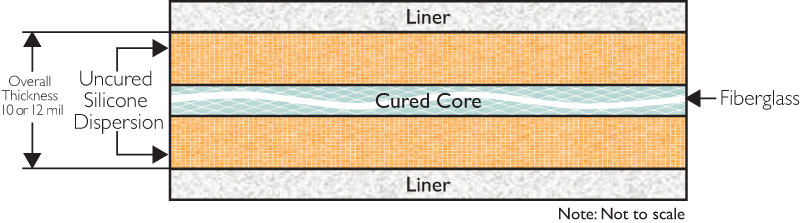

Bond-Ply LMS-HD導熱 熱固性層壓材料。產品 由高性能熱 導電低模量有機硅化合物 涂層在固化的核心,雙內襯 保護膜。

低模量硅酮 設計有效吸收機械應力 裝配水平的CTE失配引起的沖擊和振動, 同時提供卓越的 熱性能(與PSA技術)和 長期誠信。

Bond-Ply LMS-HD將 通常被用于結構動力 秉承 組件和印刷電路板的散熱片。

典型的應用包括:離散半導體封裝粘結到散熱器或散熱片

性能:配置可用

軋輥形式

切件

表格形式

保質期:粘結層lms-hd是熱固化材料,應存放在溫度控制的條件。建議儲存溫度范圍為5-25°C應該用來維持5個月保質期的最佳特性。

|

Property

|

Imperial Value

|

Metric Value

|

Test Method

|

|

Color

|

Yellow

|

Yellow

|

Visual

|

|

Reinforcement Carrier

|

Fiberglass

|

Fiberglass

|

***

|

|

Thickness (inch) / (mm)

|

0.010, 0.012

|

0.254, 0.305

|

ASTM D374

|

|

Continuous Use Temp (°C) / (°F)

|

-76 to 356

|

-60 to 180

|

***

|

|

Adhesion

|

|

Lap Shear @ RT (psi) / (MPa) (1)

|

200

|

1.4

|

ASTM D1002

|

|

Electrical

|

Value

|

Test Method

|

|

Breakdown Voltage, Sheet (Vac) (1)

|

5000

|

ASTM D149

|

|

Breakdown Voltage, Laminated (Vac) (2)

|

4000

|

ASTM D149

|

|

Dielectric Constant (1000 Hz)

|

5.0

|

ASTM D150

|

|

Volume Resistivity (Ohm-meter)

|

1011

|

ASTM D257

|

|

Flame Rating

|

V-O

|

U.L. 94

|

|

Thermal

|

|

Post-Cured Thermal Conductivity (W/m-K) (3)

|

1.4

|

ASTM D5470

|

|

Thermal Performance vs Lamination Method

|

|

Lamination Pressure (75 psi) (4)

|

Constant

|

IPO

|

|

TO-220 Thermal Performance (°C/W)

|

2.1

|

2.3

|

1) The ASTM D149 test method on cured LMS-HD material. No pressure was applied to the LMS-HD during the cure cycle.

2) A 1/2" diameter probe was laminated with LMS-HD to a 2" X 2" plate at 200 psi for 30 seconds, then cured with no pressure at 160°C for 6 minutes. The cured assembly was then tested per ASTM D149. This LMS-HD sample resembles a typical lamination application.

3) The ASTM D5470 (Henkel Modified) test procedure was used on post-cured LMS-HD material. The recorded value includes interfacial thermal resistance. These values are given for customer reference only.

4) TO-220 Thermal Performance testing, per The Henkel RD2010 specification for Laminates, was completed on laminated TO- 220 assemblies. Lamination was completed at 75 psi for 30 seconds for "IPO" (Initial Pressure Only) and at a constant 75 psi during the lamination and curing process for "Constant". No additional pressure was applied during TO-220 thermal performance testing.

|